Keeping your vehicle’s brake system in optimal condition is crucial for safety and performance. Neglecting brake maintenance can lead to costly repairs and, more importantly, compromise the safety of you and your passengers. Brake service and precision machining are essential for maintaining a safe and efficient brake system.

The Pro Cut on Car Brake Lathe is a specialized tool that can optimize the performance of your vehicle’s braking system. It offers precision machining to resurface brake rotors effectively, ensuring that they perform reliably and safely. Let’s learn more about this tool and why it’s essential for brake service providers.

Key Takeaways:

- The Pro Cut on Car Brake Lathe is a specialized tool that can optimize the performance of your vehicle’s braking system.

- Brake service and precision machining are essential for maintaining a safe and efficient brake system.

- Neglecting brake maintenance can lead to costly repairs and compromise the safety of you and your passengers.

Understanding the Pro Cut on Car Brake Lathe

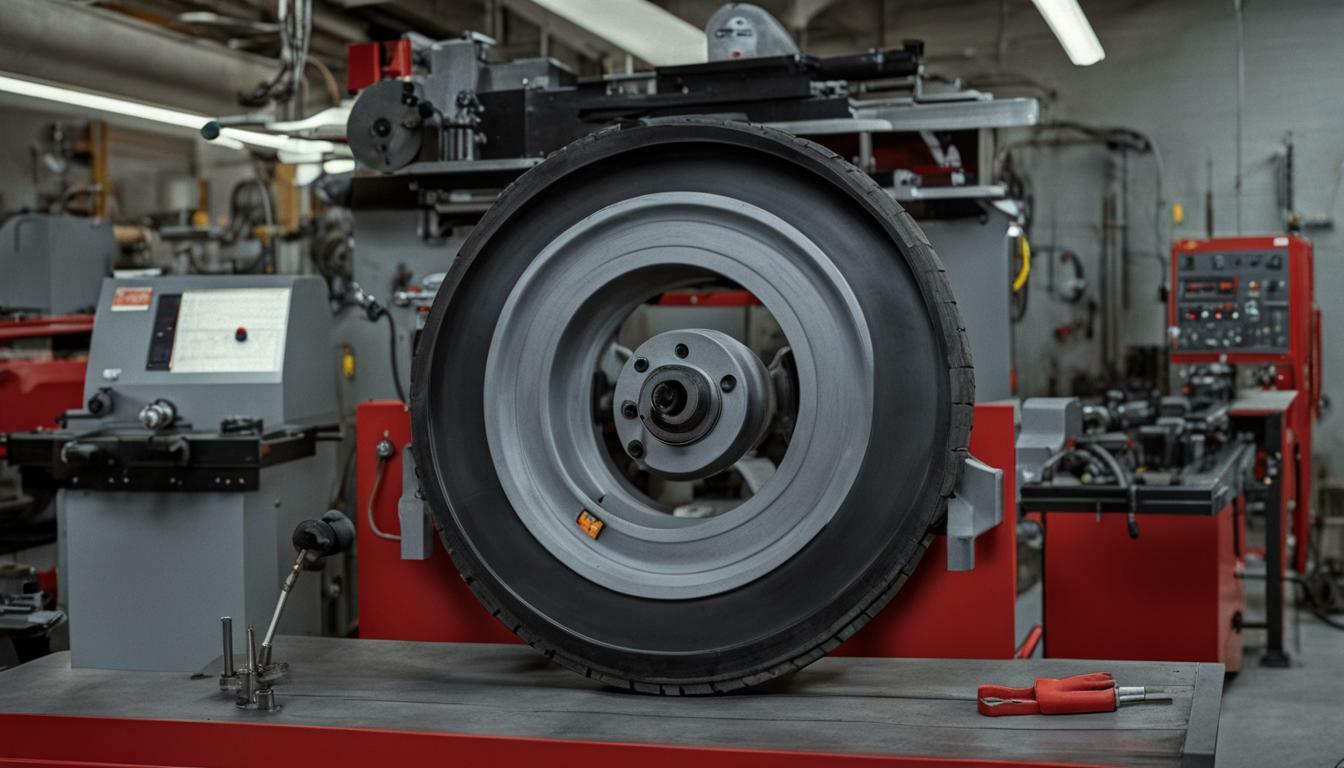

The Pro Cut on Car Brake Lathe is a specialized tool designed to enhance the performance of vehicle brake systems. This innovative technology is commonly known as an automotive brake lathe that allows for precision machining of brake rotors to achieve a smooth, even surface.

Automotive brake lathe technology has been used for decades to resurface brake discs, but the Pro Cut on Car Brake Lathe takes this process to the next level. It enables professional brake service providers to resurface brake rotors with greater accuracy and precision, resulting in optimal brake performance for vehicles.

Rotor resurfacing is a crucial aspect of brake maintenance as it removes imperfections on the surface of the rotor that can cause brake noise, vibration and uneven wear. By using the Pro Cut on Car Brake Lathe, brake service professionals can deliver high-quality services that help ensure the safety and reliability of their clients’ vehicles.

How the Pro Cut on Car Brake Lathe Works

The Pro Cut on Car Brake Lathe uses precision technology to machine brake rotors accurately. The tool is driven by an electric motor that spins the brake rotor while it is held firmly in place. The lathe’s cutting head is then slowly fed into the rotating rotor, cutting away any unevenness to achieve a smooth, even surface.

This process can be completed quickly, with some jobs taking just a few minutes. The end result is a perfectly machined rotor that performs optimally, providing the driver with a smooth and safe ride.

Overall, the Pro Cut on Car Brake Lathe is an essential tool for professional brake service providers who want to deliver high-quality services to their clients. By using this innovative technology, service providers can ensure the safety and reliability of their clients’ vehicles, while generating revenue through enhanced service efficiency and customer satisfaction.

The Importance of Brake Maintenance

Regular brake maintenance is critical to ensure optimal performance and safety for drivers and passengers. Neglecting to maintain the brake system can lead to severe consequences, such as reduced stopping power, vibrations, noise, and even brake failure. Therefore, brake maintenance should never be overlooked.

Brake maintenance involves various tasks, including inspecting the brake pads and rotors, replacing worn-out components, cleaning the brake system, and adjusting the brake calipers. It is essential to adhere to the manufacturer’s recommended maintenance schedule to ensure the brake system remains in optimal condition.

Some common signs that indicate the need for brake system repair include squealing or grinding noises, a spongy brake pedal, a vibrating steering wheel, and the brake warning light turning on. If you experience any of these signs, it is crucial to have your brake system checked by a qualified technician as soon as possible to avoid potential safety hazards.

The Process of Brake Disc Turning

The Pro Cut on Car Brake Lathe is a specialized tool that enables precision machining of brake rotors for improved performance. The process of turning brake discs using this tool involves several key steps.

- Setup: The first step is to mount the brake rotor onto the lathe using the appropriate adapter plate. The adapter plate ensures that the rotor is centered and secured in place during the turning process.

- Cutting: Once the rotor is securely mounted, the cutting process begins. The Pro Cut on Car Brake Lathe uses a computerized measuring system to scan the surface of the rotor and identify any imperfections or irregularities. It then uses a precision cutting tool to remove a small layer of metal from the surface of the rotor, creating a smooth, even surface.

- Measurement: After each pass of the cutting tool, the Pro Cut on Car Brake Lathe measures the thickness of the rotor to ensure that the correct amount of material is being removed. This ensures that the rotor remains within the manufacturer’s specifications and maintains its structural integrity.

- Finish: Once the cutting process is complete, the Pro Cut on Car Brake Lathe applies a final finishing pass to the rotor. This removes any remaining burrs or rough spots, creating a mirror-smooth surface that promotes optimal brake performance.

Overall, the process of turning brake discs using the Pro Cut on Car Brake Lathe is a highly effective way to optimize brake performance and prolong the life of the brake system. By removing imperfections and creating a smooth surface, this precision machining tool ensures optimal braking performance and enhances the safety and reliability of the vehicle.

Benefits of Pro Cut on Car Brake Lathe for Brake Service Providers

Investing in the Pro Cut on Car Brake Lathe is a smart choice for brake service providers seeking to increase efficiency, customer satisfaction, and revenue generation. This specialized tool provides precision machining capabilities that are unmatched in the industry, resulting in a superior brake service experience for vehicle owners.

The Pro Cut on Car Brake Lathe allows for quick and efficient resurfacing of brake rotors, ensuring optimal performance and safety for the vehicle. With its advanced technology and automated operation, this tool eliminates the need for manual labor, reducing the risk of errors and increasing efficiency.

Precision machining is essential for brake service, and the Pro Cut on Car Brake Lathe delivers exceptional results every time. Its ability to remove imperfections and achieve a smooth, even surface on brake discs is unparalleled, providing a superior driving experience for vehicle owners.

By utilizing the Pro Cut on Car Brake Lathe, brake service providers can enhance their reputation and attract more customers. With its precision machining capabilities, this tool can address a wide range of brake issues, delivering top-notch service that exceeds customer expectations. Additionally, the efficiency and accuracy provided by the Pro Cut on Car Brake Lathe can result in more revenue for brake service providers, allowing them to grow their business and thrive in a competitive market.

Conclusion

Investing in the Pro Cut on Car Brake Lathe for optimizing your vehicle’s brake performance is a wise choice. Regular brake maintenance is crucial to ensure optimal performance and safety, and the specialized features of this tool can help achieve that. By understanding the process of brake disc turning and the benefits of precision machining with the Pro Cut on Car Brake Lathe, you can ensure that your brake system functions efficiently and smoothly.

For professional brake service providers, the Pro Cut on Car Brake Lathe offers significant advantages. Its precision machining capabilities increase service efficiency, customer satisfaction, and revenue generation. By investing in this tool, you can enhance your brake service offerings and stand out from competitors.

Don’t neglect your brake system. Whether you’re a vehicle owner or a professional brake service provider, the Pro Cut on Car Brake Lathe is an effective solution for optimizing brake performance and ensuring safety on the road.

FAQ

Q: How does the Pro Cut on Car Brake Lathe optimize vehicle brake performance?

A: The Pro Cut on Car Brake Lathe optimizes vehicle brake performance by precision machining brake rotors, ensuring a smooth and even surface for better braking. This helps eliminate brake pulsation, noise, and vibration, resulting in improved safety and efficiency.

Q: Can the Pro Cut on Car Brake Lathe be used for all types of brake systems?

A: Yes, the Pro Cut on Car Brake Lathe is designed to work with various types of brake systems, including those found in cars, trucks, SUVs, and motorcycles. It can effectively resurface brake rotors of different sizes and materials.

Q: How often should brake rotors be resurfaced with the Pro Cut on Car Brake Lathe?

A: The frequency of brake rotor resurfacing depends on various factors, such as driving conditions, vehicle weight, and brake pad quality. However, it is generally recommended to have the brake rotors checked and resurfaced every 15,000 to 20,000 miles or as needed to maintain optimal braking performance.

Q: Can the Pro Cut on Car Brake Lathe fix brake rotor warping?

A: Yes, the Pro Cut on Car Brake Lathe can address brake rotor warping by removing uneven surfaces and imperfections. This helps restore the flatness of the rotor and improves brake performance. However, severe cases of rotor warping may require replacement instead of resurfacing.

Q: Is the Pro Cut on Car Brake Lathe easy to use?

A: Yes, the Pro Cut on Car Brake Lathe is designed to be user-friendly and intuitive. It comes with clear instructions and adjustable settings to accommodate different rotor sizes and machining requirements. With proper training and practice, brake service providers can easily operate the Pro Cut on Car Brake Lathe.

Q: Are there any safety precautions to consider when using the Pro Cut on Car Brake Lathe?

A: Yes, it is important to follow all safety guidelines provided by the manufacturer when using the Pro Cut on Car Brake Lathe. This includes wearing appropriate protective gear, ensuring the work area is well-ventilated, and taking necessary precautions to prevent accidents or injuries during the machining process.

- Delta Midi Lathe 46-250 Performance - August 27, 2023

- Understanding the Different Parts of a Lathe Machine - August 27, 2023

- Explore Different Lathe Tool Holder Types for Your Projects - August 27, 2023