Lathe machines have been a vital tool in the machining industry for centuries. From cutting and shaping metal to wood and plastics, the lathe machine has been the go-to equipment for precise and efficient machining operations. But how do these machines work, and what are the key components that make them function?

In this article, we will provide a comprehensive guide to the various parts of a lathe machine. We will explore the functions of each component and how they work together to create a seamless machining process. Whether you’re a seasoned machinist or a beginner, this guide will provide you with a broad understanding of the essential parts of a lathe machine.

Key Takeaways:

- The lathe machine is a crucial tool in machining operations.

- Understanding the various parts of the lathe machine is essential to maximizing its efficiency.

- The parts of a lathe machine include the spindle, chuck, bed, headstock, tools, and accessories.

- Each component plays a vital role in the overall performance of the machine.

Understanding Lathe Machine Parts

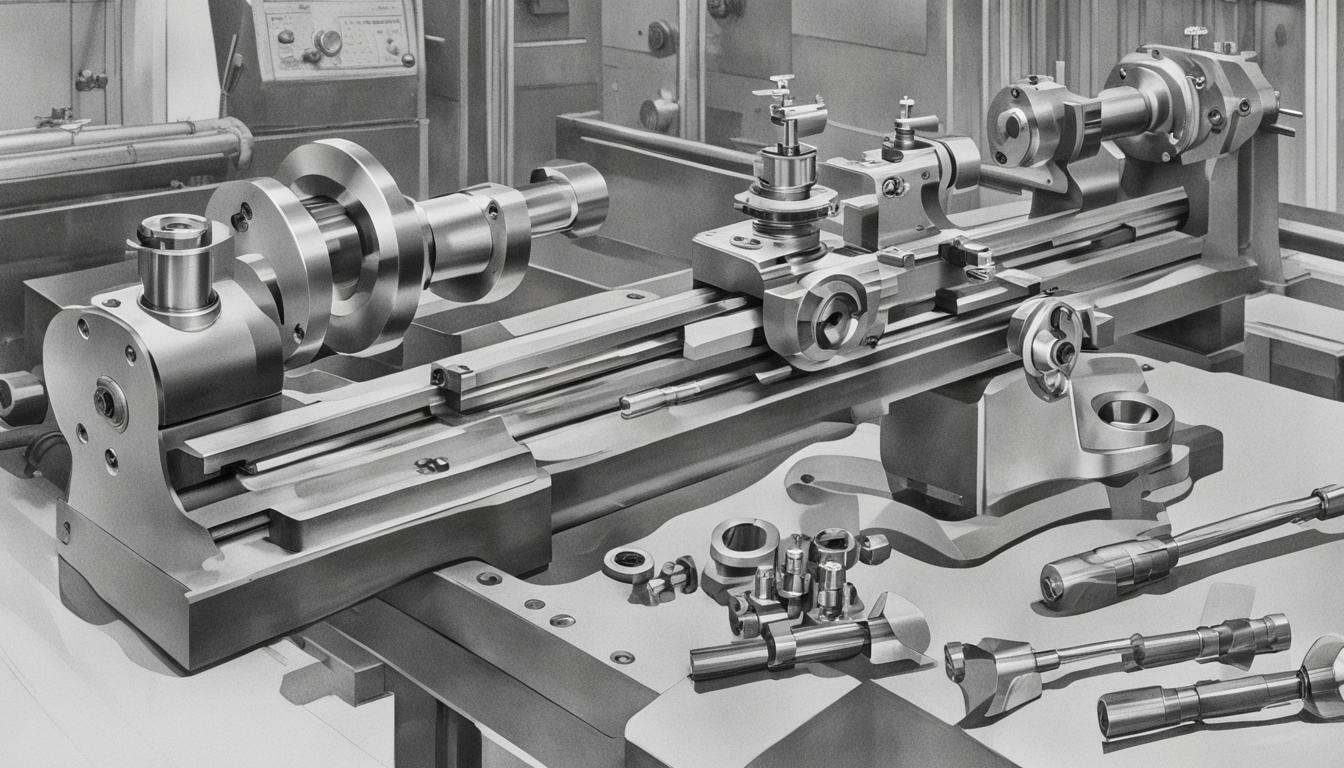

A lathe machine is composed of different parts, each with its specific function and role in the machining process. Understanding these components is crucial to operate the machine effectively and achieve precise results. In this section, we will discuss the various parts of a lathe machine and their functions.

The Bed

The bed is the base of the lathe machine and supports all other components. It is usually made of cast iron and has a flat surface on which the workpiece is mounted. The bed provides stability, ensuring that the machine does not vibrate during operation. It also has guide rails that help the carriage move back and forth smoothly.

The Headstock

The headstock is located on the left side of the lathe machine and holds the spindle and the driving mechanism. The spindle rotates the workpiece, and the driving mechanism provides power to the spindle. The headstock also houses the gearbox, which allows the operator to change the spindle speed to suit the workpiece’s requirements.

The Tailstock

The tailstock is located at the opposite end of the lathe machine from the headstock. It can move back and forth along the bed’s guide rails, allowing the operator to adjust the workpiece’s position. The tailstock also provides support to the workpiece, preventing it from bending or deflecting during machining.

The Carriage

The carriage is located between the headstock and the tailstock and moves along the bed’s guide rails. It holds the cutting tool and moves it along the workpiece’s surface, removing material and creating the desired shape. The carriage also has a cross-slide, which allows the operator to adjust the cutting tool’s position vertically and horizontally.

The Apron

The apron is located below the carriage and contains the mechanism for feeding the cutting tool into the workpiece. It also houses the gear train, which drives the carriage and the cross-slide.

The Cutting Tool

The cutting tool is the component that removes material from the workpiece. It is mounted on the carriage and can be adjusted to suit the desired depth and shape of the cut. Cutting tools come in different shapes and sizes, depending on the type of machining operation and the material being worked on.

The Chuck

The chuck is the component that holds the workpiece in place during machining. It is mounted on the spindle and can grip the workpiece securely, allowing it to rotate along with the spindle. There are different types of chucks, such as three-jaw and four-jaw chucks, each with its specific advantages and disadvantages.

Understanding the different parts of a lathe machine is essential to operate it efficiently and achieve precise results. In the next section, we will focus specifically on the spindle and chuck, their features, functions, and maintenance.

Lathe Machine Spindle and Chuck

The spindle and chuck of a lathe machine play a crucial role in its machining operations. The spindle is responsible for rotating the workpiece, while the chuck securely holds it in place. Understanding the features and functions of these two components is essential for achieving accuracy and precision in machining.

The spindle is typically located at the headstock of the lathe machine. It is responsible for holding and rotating the workpiece as the cutting tool moves along its surface. Spindles can be of various types, including belt-driven, gear-driven, and modern ones that use electric motors. Belt-driven spindles are popular for their simplicity and affordability, while gear-driven spindles offer higher torque and stability. Electric motor-driven spindles offer the most advanced technology, providing high torque and precise control over the speed and rotation of the workpiece.

The chuck is used to securely hold the workpiece in place while it is being machined. Chucks can be of various types, including three-jaw, four-jaw, and collet chucks. Three-jaw chucks are versatile and can hold a wide range of workpiece shapes and sizes, while four-jaw chucks are more precise and can hold irregularly shaped workpieces. Collet chucks are used for holding smaller workpieces that require higher precision.

Proper maintenance and troubleshooting of the spindle and chuck are crucial for ensuring the longevity and reliability of a lathe machine. Regular inspection and cleaning of the spindle and chuck can prevent wear and tear and ensure smooth operation. Any unusual noise or movement should be promptly addressed to avoid further damage to the machine.

Lathe Machine Bed

The lathe machine bed is the foundation of the entire machine, providing support for all the other components. It is the base on which the headstock, tailstock, carriage, and other components are mounted, and it is crucial for the stability and precision of the machining process. The lathe machine bed must be made of materials that offer high rigidity and dampening properties, such as cast iron or steel.

| Feature | Description |

|---|---|

| Length | The length of the bed determines the maximum length of stock that can be machined. |

| Width and Depth | The width and depth of the bed provide stability and help to dampen vibrations during machining. |

| Guideways | The guideways are the surfaces on which the carriage and tailstock slide back and forth. They must be precisely machined to ensure smooth and accurate movement. |

Regular maintenance of the lathe machine bed is essential to prevent wear and tear that can lead to inaccuracies in machining. Users must keep the bed clean and free of debris, and apply lubrication to the guideways to reduce friction.

The lathe machine bed is a critical part of the machine that enables precision and accuracy in machining. A properly maintained bed ensures the smooth and reliable operation of the machine, making it an indispensable component for all machining applications.

Lathe Machine Headstock

The headstock is an essential component of the lathe machine. It is located on the left side of the lathe bed and houses the spindle. The spindle is the rotating shaft that holds and rotates the workpiece during machining operations.

The headstock has several key features that contribute to the performance of the lathe machine. These include:

- Speed Control: The headstock allows for variable speed control for the spindle, enabling operators to adjust the rotational speed to suit the specific requirements of the machining operation.

- Chuck Mounting: The headstock also provides a mounting point for the chuck, which is used to hold and secure the workpiece during machining operations.

- Motor: The headstock houses the motor that drives the spindle, providing the power necessary to rotate the workpiece.

- Bearing Support: The headstock has a bearing support system that ensures the spindle rotates smoothly and accurately.

There are different types of headstocks available for lathe machines, including:

- Fixed Headstock: This type of headstock is fixed in place and is ideal for machining long workpieces that require a high degree of accuracy.

- Sliding Headstock: A sliding headstock can be adjusted to accommodate different workpiece lengths, making it a versatile option for machining operations.

- Swiveling Headstock: This type of headstock can be swiveled to enable angled cuts, making it suitable for more complex machining operations.

Proper maintenance of the headstock is crucial for the smooth operation of the lathe machine. Regular inspection and lubrication of the bearings and motor are necessary to prevent wear and tear and ensure optimal performance.

“The headstock is a critical component of the lathe machine, and understanding its features and functions is crucial for achieving accurate and efficient machining operations.”

Lathe Machine Tools and Accessories

Lathe machines are versatile tools that can perform various machining operations with the help of different tools and accessories. Here’s a closer look at some of the most commonly used lathe machine tools and accessories:

Cutting Tools

The cutting tool is a vital component in any machining operation, and it is no different in a lathe machine. Various types of cutting tools are available in the market, including turning tools, facing tools, boring tools, and parting tools. Each tool is designed to perform a specific type of cutting operation, making them essential in the machining process.

Tool Holders

To hold the cutting tools securely in place, a lathe machine requires tool holders. A tool holder is a device that clamps the cutting tool in place and allows for easy adjustment and positioning. The type of tool holder used will depend on the type and size of the cutting tool being used.

Chucks

A chuck is a device that holds the workpiece in place while it is being machined. Lathe machines use various types of chucks, including three-jaw chucks, four-jaw chucks, and collet chucks. Each type of chuck has its own benefits and drawbacks, making it important to choose the right one for the job.

Steady Rests

A steady rest is a device used to support long or thin workpieces during machining operations. It ensures that the workpiece remains stable and does not deflect or vibrate during machining, resulting in a more precise finished product. Different types of steady rests are available, including ball-bearing steady rests and roller-bearing steady rests.

Tailstocks

A tailstock is a device used to support one end of the workpiece during machining operations. It allows for the accurate centering of the workpiece and provides additional support, resulting in greater stability and precision during machining. Tailstocks can be manually or automatically operated, depending on the type of lathe machine.

Attachments

Various attachments can be added to a lathe machine to further enhance its capabilities. Examples of attachments include milling attachments, grinding attachments, and drilling attachments. These attachments allow for the performance of additional machining operations, making the lathe machine even more versatile.

Understanding the different tools and accessories used in lathe machines is essential to achieving optimal results. By selecting the right tools and accessories for the job, machinists can ensure a more precise and efficient cutting process, resulting in high-quality finished products.

Conclusion

In conclusion, understanding the various parts of a lathe machine is crucial for both novice and experienced machinists. By gaining knowledge of the components, their functions and importance, a machinist can make informed decisions about how to optimize machine performance and identify potential issues before they escalate.

In this comprehensive guide, we have explored the key components of a lathe machine, including the spindle, chuck, bed, headstock, tools, and accessories. We have discussed their features, types, and how they contribute to the machining process, as well as the importance of maintenance and troubleshooting.

As you embark on your machining endeavors, we encourage you to apply this knowledge and continue to deepen your understanding of the lathe machine. With the right tools and expertise, a lathe machine can be a powerful and versatile tool in any machinist’s arsenal.

Thank you for taking the time to read this guide, and we wish you the best of luck in all your machining endeavors.

FAQ

Q: What are the main parts of a lathe machine?

A: The main parts of a lathe machine include the spindle, chuck, bed, and headstock. Additionally, there are various tools and accessories that can be used with a lathe machine.

Q: What is the function of the lathe machine spindle?

A: The spindle in a lathe machine holds and rotates the workpiece. It provides the necessary power and motion for the machining operations.

Q: How do I maintain the lathe machine chuck?

A: To maintain the lathe machine chuck, it is important to clean it regularly and remove any debris or coolant that may accumulate. Lubricating the chuck and inspecting it for any signs of wear or damage is also recommended.

Q: What is the role of the lathe machine bed?

A: The lathe machine bed provides a rigid and stable platform for mounting the various components of the machine. It ensures accurate and precise machining by minimizing vibrations and maintaining alignment.

Q: What are the different types of lathe machine headstocks?

A: The headstock of a lathe machine can be classified into various types, such as geared headstock, belt-driven headstock, and electronic variable speed headstock. Each type has its own advantages and is suitable for specific machining requirements.

Q: What are some common lathe machine tools and accessories?

A: Common lathe machine tools include cutting tools, tool holders, boring bars, drill chucks, and live centers. Accessories can range from steady rests and tailstocks to faceplates and collets.

- Delta Midi Lathe 46-250 Performance - August 27, 2023

- Understanding the Different Parts of a Lathe Machine - August 27, 2023

- Explore Different Lathe Tool Holder Types for Your Projects - August 27, 2023